Recommendations for the use of cutting-off wheels

Proper use of the cutting blade is essential to achieve effective results and ensure safety. To avoid reducing productivity and increasing the risk of danger, you must follow the basic guidelines. Here you will find important tips and practical advice for the correct use of cutting blades that will help you ensure high-quality cutting results and safety during your work.

Recommendations for use:

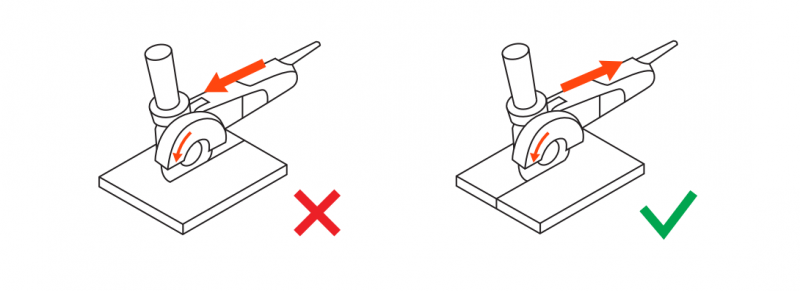

Cutting direction

When working with metal cutting wheels, it is recommended to cut in the direction of travel. The wheel should rotate in the opposite direction - away from the operator. During this cutting process, the sparks are directed towards the operator.

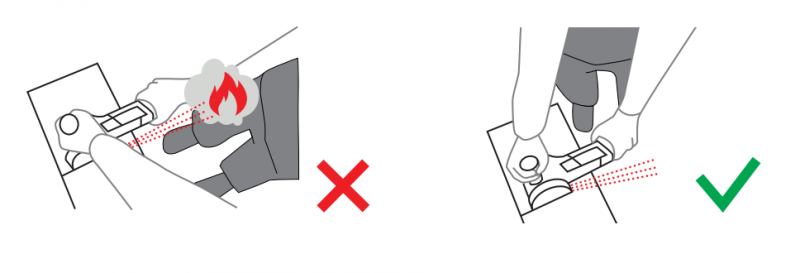

Sparks

During operation, the operator should position himself to avoid direct contact with sparks on clothing.

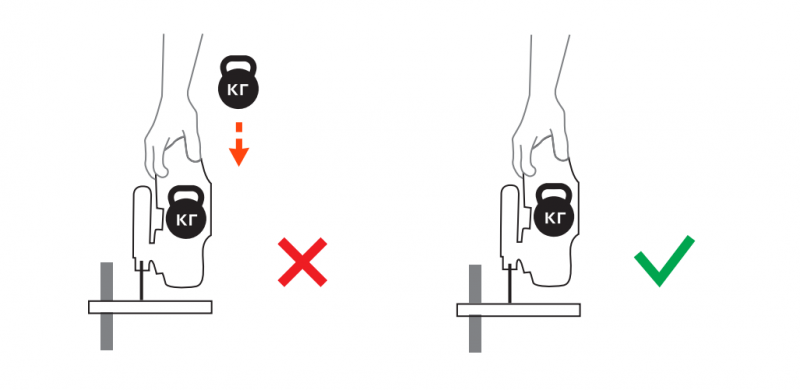

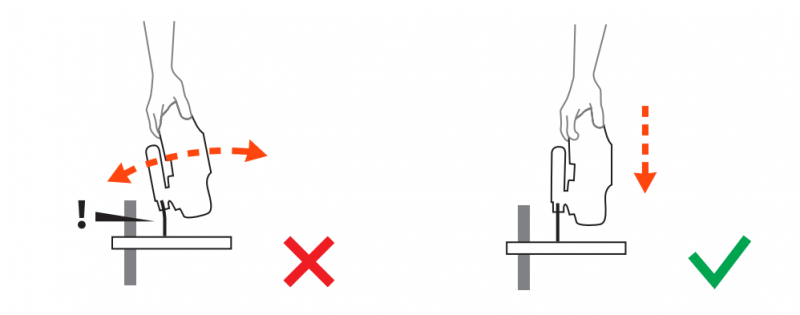

Cutting angle and pressure on the wheel

Do not apply additional force during operation, as the optimal pressure is generated by the weight of the angle grinder itself.

Always hold the wheel perpendicular to the workpiece. The workpiece must be securely clamped. It is recommended that the workpiece be clamped as close to the cutting point as possible to prevent vibration and sideways movement of the wheel.

Mounting on the angle grinder

Before mounting the disc on the angle grinder, make sure that the clamping flanges are not damaged or worn, as they are responsible for securing the disc in place.

Table of the ratio of wheel size to speed per minute

Maximum operating speed - 80 m/s

|

Diameter of the wheel, ⌀ |

115 |

125 |

150 |

180 |

230 |

300 |

355 |

400 |

|

Max. speed |

13300 |

12250 |

10200 |

8500 |

6650 |

5100 |

4400 |

3800 |

To achieve the highest quality results and maximum service life of the disc, operate at a speed close to the maximum value (see the table).

Possible problems when working with metal grinding wheels and ways to solve them

|

Possible problems |

Possible cause |

Solution |

|

The wheel overheats |

Low power of the angle grinder |

Use a more powerful angle grinder |

|

The cutting-off wheel is too thick |

Use a thinner wheel |

|

|

Excessive wear and tear |

Too low a speed |

Increase the speed |

|

Workpiece is not properly clamped |

Clamp the workpiece closer to the workpiece |

|

|

Too much pressure is applied |

Reduce the pressure force |

|

|

Uneven cut |

The disc is too thin for the work being performed |

Use a thicker wheel |

|

Disc is completely worn out |

Replace the disc with a new one |

|

|

Breaking the circle |

Improper use of the angle grinder |

Avoid side pressure on the wheel |

|

Too low a speed |

Increase the speed |

|

|

Incorrect diameter of the clamping flange |

Use a clamping flange with the correct diameter |

|

|

The cutting-off wheel is used for grinding |

The cutting-off wheel must not be used for grinding |

|

|

Incorrect clamping of the workpiece |

Clamp the workpiece closer to the workpiece |

|

|

The disc is “wearing off” |

Pressure flange is dirty or worn |

Clean the pressure flange or replace it |

|

Defective angle grinder |

Replace the angle grinder |

Always follow the following rules when working with metal discs

- Store the cutting-off wheels horizontally on a flat surface.

- Before use, visually inspect the discs for possible damage during transportation or storage.

- Never use a damaged wheel.

- When working, use a protective guard that must cover at least half of the wheel and protect the operator in the event of a possible wheel breakage.

- Always unplug the angle grinder from the power outlet when changing the wheel.

- Make sure that the speed of the angle grinder corresponds to the maximum speed indicated on the wheel.

- Securely clamp the workpiece before starting work.

- During breaks or after work, store the angle grinder in a manner that prevents possible damage to the wheel.

- Always wear personal protective equipment:

safety goggles, ear protection, respirator, and gloves.

Basic precautions when working with metal grinding wheels

- Do not store the discs in a room with high humidity.

- Never exceed the maximum operating speed and rpm indicated on the disc.

- Do not use excessive force when mounting the wheel on the angle grinder spindle.

- Do not use flanges that are damaged or dirty.

- Do not overtighten the mounting nut or mounting flange. Doing so may cause deformation of the flange and result in damage to the wheel.

- Do not apply side pressure to the disc during operation.

- Do not stop the wheel by applying pressure to its surface. Always turn off the angle grinder and wait for the wheel to stop rotating.

- Do not apply excessive force to the wheel during operation, which will slow down the rotation speed of the angle grinder.

- Do not grind with the cutting-off wheel on metal.